- Home

- Company

- Services

- Product

- DEIF MARINE PRODUCT

- DEIF LAND PRODUCT

- AGC 150 Advanced Genset Controller

- AGC 200 Advanced Genset Controller

- AGC 4 Advanced Genset Controller

- AGC 4 MK II

- ALC-4 Automatic Load Controller

- CGC 200 Compact genset controller

- CGC 400 Compact Genset Controller

- İE 250

- SGC 110 SİNGLE GENSET CONTROLLER

- SGC 120 GENSET CONTROLLER

- SGC 120 MK II GENSET CONTROLLER

- SGC 410 GENSET CONTROLLER

- SGC 420 GENSET CONTROLLER

- SGC 420 MK II

- DEIF SOLAR PRODUCT

- GAS TURBINE PARTS

- GE MARK VİE SERİES

- MV GEAR SWITCH

- THERMOCOUPLE CONAX

- Transformer

- UPS AND SHARE POWER

- Project

- References

- Blog

- Contact

Mark VI

The SPEEDTRONIC™ Mark VI

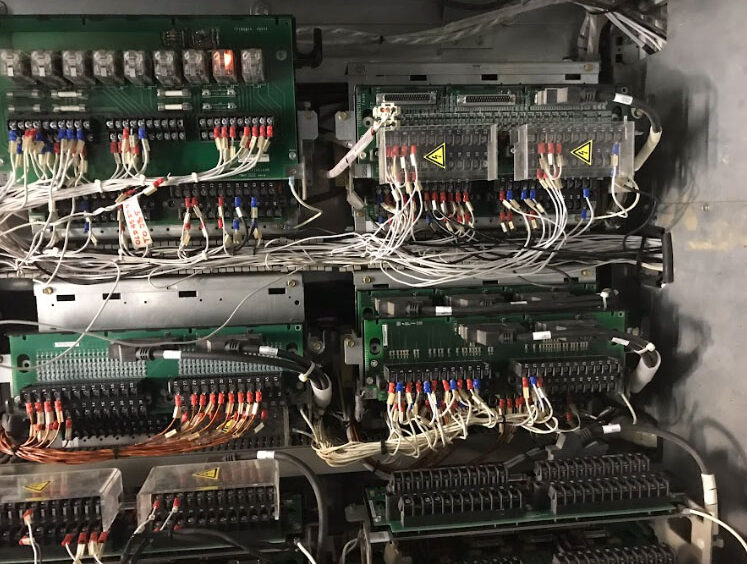

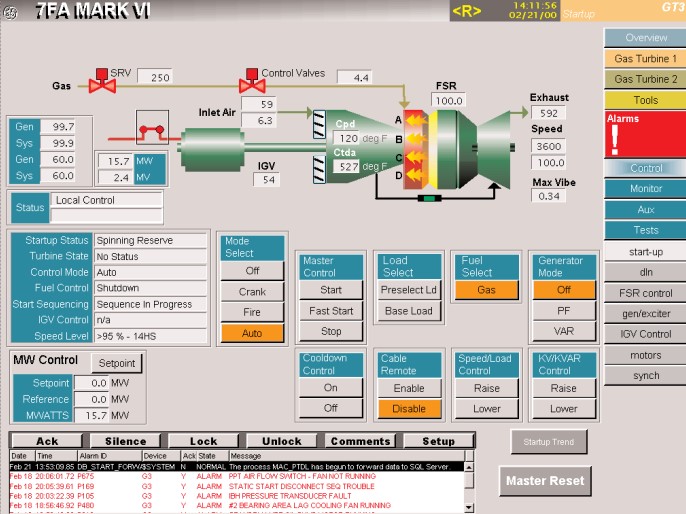

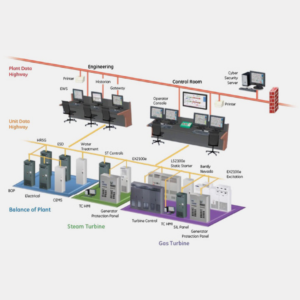

The SPEEDTRONIC™ Mark VI turbine control is the current state-of-the-art control for gas turbines. It is designed as a complete integrated control, protection, and monitoring system for generator and mechanical drive applications of gas and steam turbines. It is also an ideal platform for integrating all power island and balance-of-plant controls. Hardware and software are designed with close coordination between gas turbine design engineering and controls engineering to insure that your control system provides the optimum turbine performance and you receive a true “system” solution.

Order Now

- Description

- Reviews (0)

Reviews

There are no reviews yet.